PRODUCTS

cases

LMS is your expert partner.

HIGH AUTOMATION, NEW GENERATION,

MORE INNOVATION

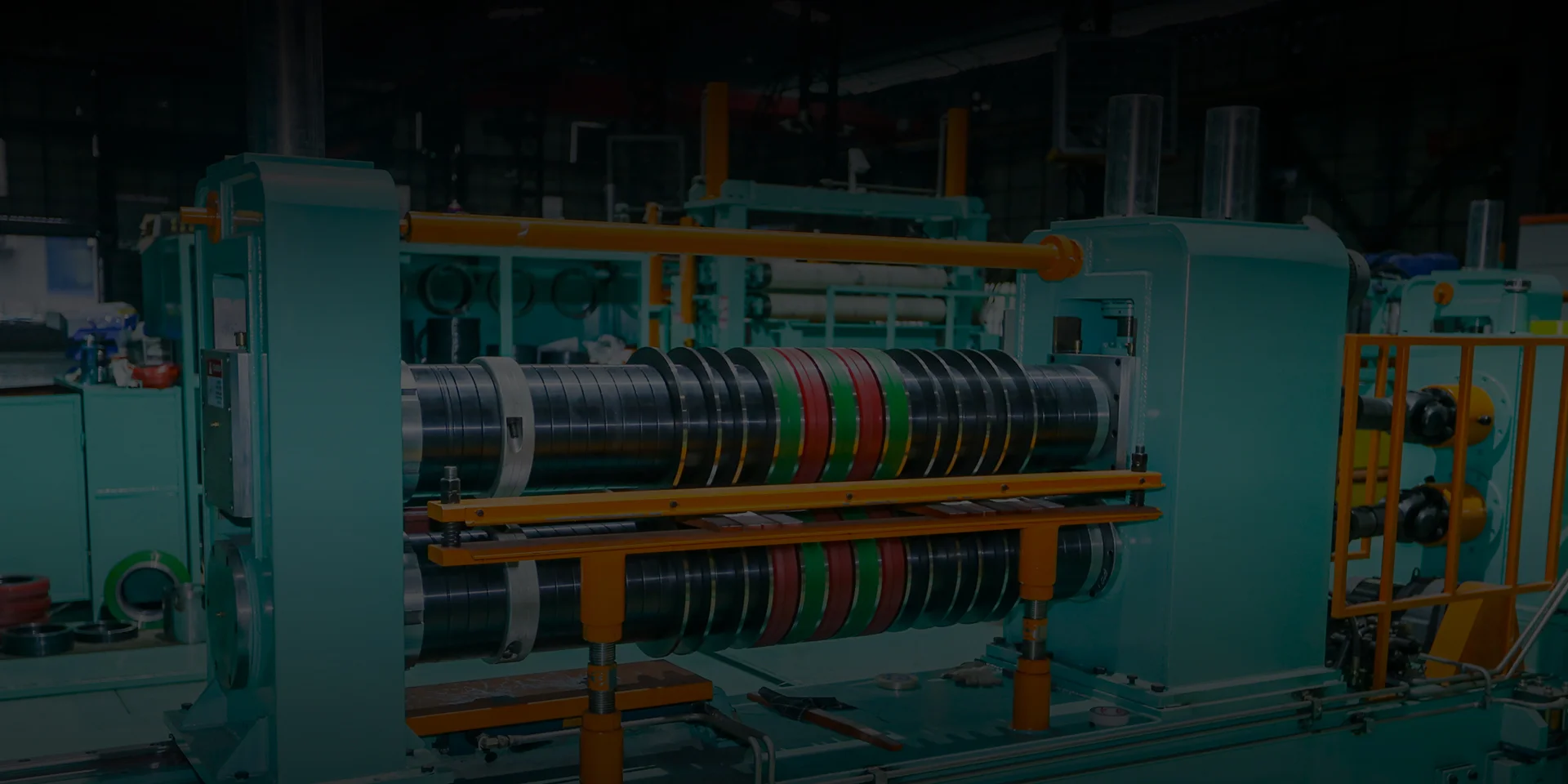

Guangzhou LMS Machinery Co., Ltd, established in 2010, is an expert partner for slitting lines and cut to length line machines. Our core expertise lies in the research and production of metal strip slitting lines, metal coil cut-to-length lines, rotary-shear cut-to-length lines, swing shear lines, flying shear lines, as well as the combination of slitting and cut-to-length lines.

Established in 2010

LMS workshop in

Annual output

Continents

LATEST NEWS

Feb 28,2026

Understanding Quality Metal Coil Decoilers and Cut to Length Solutions

In the metal processing industry, the concepts of quality metal coil decoilers and cut-to-length solutions are pivotal for optimizing manufacturing and production. A metal coil decoiler plays a significant role in handling coils of metal material, allowing for efficient unrolling and feeding into various processing machines. When paired with cut-to-length systems, these machines enable manufacture

Feb 25,2026

Slitting Line – High-Precision Industrial Machine for Efficient Material Conversion

Slitting line is an industrial machine that precisely cuts large rolls of materials into narrower strips, ensuring efficiency and consistent quality.

Feb 04,2026

LMS Slitting Line Loading And Shipping

Following the client-approved FAT, LMS Machinery now focuses on the final preparations for slitting machine line delivery.