- 产品描述

- 参数组

-

- Commodity name: Dual Slitter Slitting Line

Discover our high-performance Dual Head Slitting Line. Engineered for minimum downtime, this automated slitting system features two independent heads for continuous processing of steel, aluminum, and non-ferrous coils.

Dual Head Slitter Slitting Line

Overview:

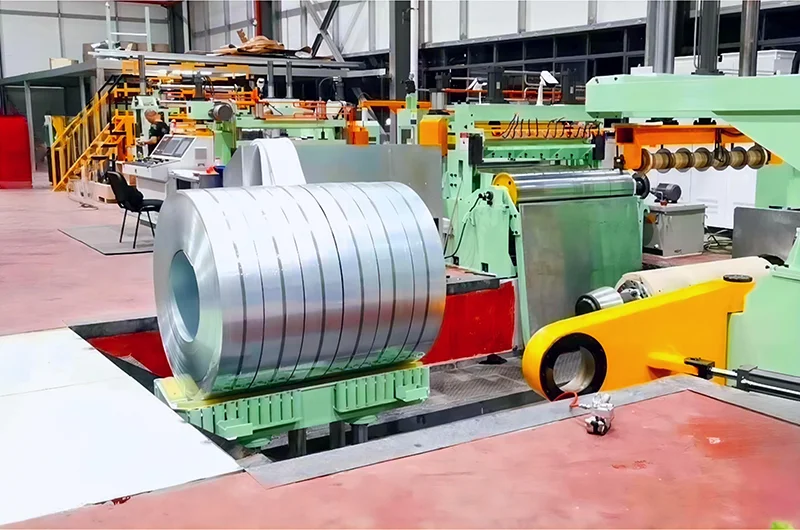

In high-volume metal processing, downtime is the enemy of profitability. Conventional slitting lines create inevitable bottlenecks during tooling changeovers. Our engineered-for-performance Dual Head Slitting Line redefines productivity by eliminating these bottlenecks entirely. By enabling simultaneous coil cutting and slitting toolings setup, this advanced system guarantees maximum uptime, unparalleled flexibility, and a rapid return on investment for the world's most demanding metal service centers and manufacturing facilities.

Primary Function:

Our slitting line features two fully independent slitting heads mounted on a heavy-duty rail shuttle system. The machine is designed to simultaneously maximize productivity and flexibility. While one slitting head is in the cutting position processing steel strips, operators can safely and efficiently install slitting knives on the second head in the preparation area. This parallel processing approach ensures the machine spends maximum time in production.

Parallel Operation:

Station A (Cutting Station): Head 'A' is locked into the coil processing position. One head is in position for high-speed coil slitting. Material flows through it, being slit at the programmed line speed.

Station B (Setup Station): Head 'B' is stationed in the setup area. Operators can safely and offline prepare the next order's tooling, set spacers, and make all adjustments. This process is completely isolated from the active machining zone.

Seamless Switchover: Upon completion of the current order, the shuttle system automatically exchanges the heads in minutes with a single button command. Production resumes immediately.

Continuous Production: The line immediately restarts with the new job. Head 'A' now becomes the setup head for the subsequent order, creating a perpetual cycle of production.

Application:

This dual-head configuration is particularly useful for high-volume production enterprises where efficiency is critical. Our lines are configured to precisely handle the specific characteristics of your materials:

Mild Steels: Cold Rolled (CRS), Hot Rolled (HRS)

Coated Steels: Galvanized (GI), Galvalume (AZ), Aluzinc

Stainless Steels: 200, 300, & 400 Series (e.g., 304, 316, 430)

Non-Ferrous Metals: Aluminum, Copper, Brass

Specialty Alloys: Silicon Electrical Steel, High-Tensile Strength Steel

Pre-Painted Metals: PPGI/PPGL (Color Coated)

Dual Head Slitting Line Video

LMS SLITTING LINEDual Head Slitting Line: Minimize Downtime, Maximum Productivity

Revolutionize your metal processing with our advanced dual-head slitting technology designed for high production operation

Typical Line Configuration

Our dual head slitting line is engineered for the high demanding production requirements with unparalleled efficiency

Hydraulic Decoiler

Entry coil car transports raw metal coil from storage saddle and lift to uncoiler mandrel. Mandrel expands to hold inner core of coil tightly. Auto decoiling.

Peeler Machine & Loop Pit

Strip peeler threads the metal plate. Entry rough leveler flattens strips and entry shearer cuts off uneven metal end.

Slitting Machine

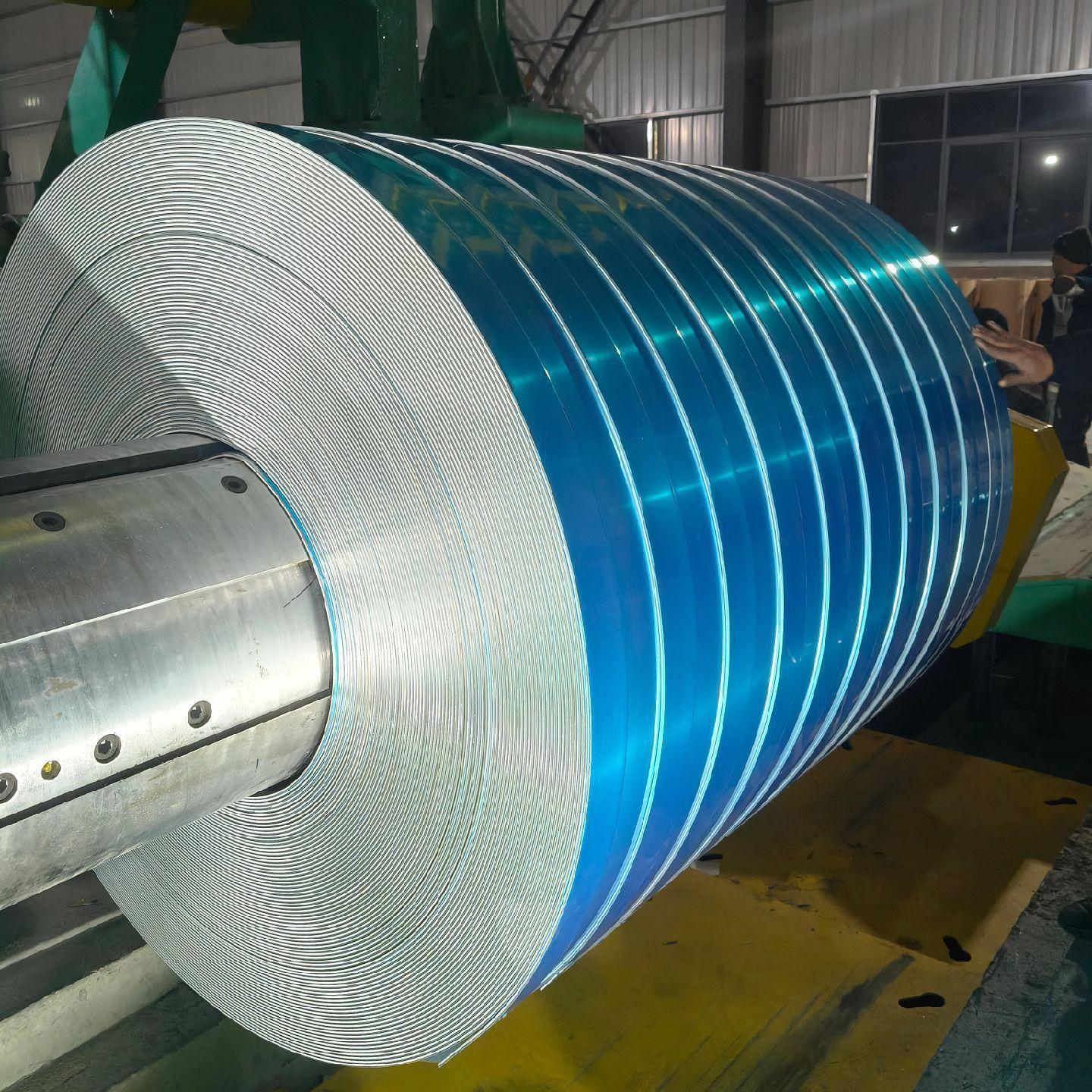

Side guiding positions the metal strip. Slitter arbors rotate and circular knives cut coils longitudinally.

Scrap baller

Scrap ballers auto follow slitting speed and rewind slitted scrap. Winding tension and speed is adjustable. The scraps are discharged by hydraulically.

Loop Pit & Pre-dividing

Looping pit offer storage space for slitted strips. Pre-dividing shafts separate strips before after exit looping pit.

Tensioning & Recoiler

Felt pad tension controls the pull from the recoiler to wind the slit strands into tight, precise coils. .

Advanced Technology

Engineered for performance, built for durability, designed for productivity

Revolutionary Dual-Head Design

Parallel Operation System

One slitting head processes material at high speed while operators safely prepare the next job on the second slitter head offline, completely eliminating production stoppages.

Arbor Height Digit Display

Motors drive precise automatic setting of knife gaps and arbor height data display, eliminating human error and increasing setup speed by 90%.

Hydraulic Nut Locking

Arbors end are locked by hydraulic nuts. Stress-relieved welded frames, premium alloy steel spindles, and P5 bearings ensure long-term precision.

Advance Control & Monitoring

Advanced Diagnostics

Integrated fault diagnosis system provides early warnings for potential issues and suggests maintenance schedules to prevent unplanned downtime.

Line Monitor Camera

Operators can monitor the entire process in real time via the central display, which shows live camera views of the uncoiler, slitting section, exit loop pit, and recoiler.

Remote Support Capability

Optional remote I/O PLC allows our technicians to provide support, diagnostics, and software updates without onsite visits.

Technical Specifications

Comprehensive specifications for our dual head slitting lines

Parameter Specification Max. Coil Width 1250mm / 1500mm / 1650mm / 2000mm (Custom widths available) Max. Material Thickness 4.0mm/ 6mm / 8mm (dependent on material tensile strength) Min. Slit Width 25mm / 50mm (dependent on arbor diameter and spacer system) Max. Coil Weight 10,000 kg / 20,000 kg / 30,000 kg (Custom options available) Inner Diameter (I.D.) 508mm (20") / 610mm (24") Max. Outer Diameter (O.D.) 1200mm - 2000mm Max. Line Speed Up to 230 m/min (dependent on material and width) Arbor Diameter φ160mm / φ200mm / φ220mm (Hardened and ground, dynamically balanced) Arbor Support NSK Bearing (For superior rigidity and vibration control) Drive System AC Motors/ DC Motors / Servo Motors with gearboxes Control System Siemens PLC / Speed controller / ABB Power Requirements 380V / 415V / 480V, 50/60Hz (Custom configurations available) Installed Power Approx. 450kW - 600kW (Dependent on line configuration) Industry Applications

Our dual head slitting lines serve a wide range of industries with precision and efficiency

Metal Service Centers

Ideal for high-volume processing of various materials and thicknesses with quick changeover between orders.

Automotive Parts Manufacturing

Precision slitting for body panels, chassis components, and structural parts with consistent quality.

Home Appliance Manufacturing

Processing of coated and pre-painted steels for refrigerators, washing machines, and HVAC units.

Construction & Building Materials

Slitting of roofing, cladding, and profiling materials with high efficiency and precision.

Transformer & Electric Motor Production

Precision slitting of silicon steel for laminations with burr-free edges and tight tolerances.

Aerospace & Precision Engineering

Processing of specialty alloys and high-strength materials with exceptional accuracy.

How It Works

The revolutionary dual-head slitting process for maximum productivity

1Loading & Setup

Coil is loaded onto the pay-off reel while the first slitting head is being prepared

2Active Slitting

First head processes material at high speed while second head is being set up offline

3Quick Changeover

After previous slitted coils are output, shuttle system exchanges heads in under 30 minutes

4Continuous Processing

Second slitter head begins immediate processing while first head is prepared for next job

How to Choose Your Slitting Line?

Contact our engineering team today for a free consultation and customized solution for your production needs

Request Quote