Customized Light Gauge Slitting Line

Oct 29,2025

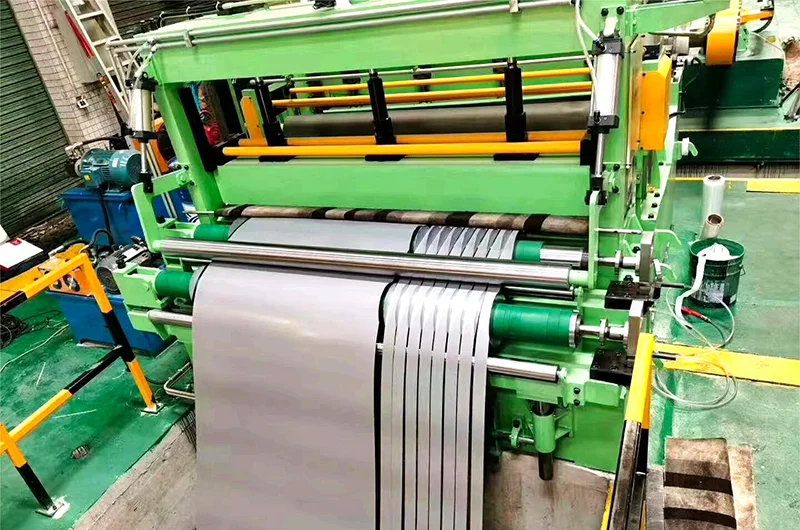

A light gauge slitting line is a specialized industrial equipment. It is designed to slit wide coils of light - gauge materials, such as thin steel or aluminum sheets, into narrower strips with high precision. With advanced control systems, it ensures smooth operation, high productivity, and excellent slitting quality, meeting diverse industrial needs.

Light Gauge Slitting Line

Light gauge slitting line is suitable for thin metal material range from 0.3 to 4.0mm thick, designed to cut metal coils into narrower widths in high precision.

1.Function:

These lines operate at high speeds, with typical speeds ranging from 120 m/min to 200 m/min in automatic mode. The slitting process preserves the surface quality of the metal, which is particularly important for materials used in exposed applications like automotive and construction.

2. Structure:

Light Gauge Slitting Lines are equipped with advanced automation features, such as automatic correction levelers and PLC control systems, which enhance efficiency and reduce manual intervention. The configuration can be customized to process a wide range of materials, including stainless steel, aluminum, carbon steel, electrical steel, and more.

3. Application:

Automotive Industry: Used for producing precise metal strips for car bodies, engines, and other components.

Construction Industry: Essential for manufacturing roofing materials, structural supports, and other construction elements.

Appliance Manufacturing: Used in the production of components for household appliances like refrigerators, washing machines, and dishwashers.

Video

The Light Gauge Slitting Line is a precision processing system designed for cutting thin metal coils into narrower strips with exceptional accuracy and efficiency. Suitable for material thicknesses ranging from 0.3mm to 4.0mm, this equipment ensures clean, burr-free edges and consistent coil widths, making it ideal for high-performance industrial applications. The Light Gauge Slitting Line operates at high speeds—typically between 120 m/min and 200 m/min—while maintaining excellent surface quality, which is critical for exposed metal products in industries such as automotive and construction.

Engineered with advanced automation and intelligent control systems, the Light Gauge Slitting Line integrates PLC controls, automatic tension regulation, and precision leveling technology to guarantee stable and efficient operation. Its modular structure can be customized to process various materials, including stainless steel, carbon steel, aluminum, copper, and electrical steel. The robust slitting head design allows rapid blade adjustment and easy maintenance, improving production flexibility and minimizing downtime.

In terms of application, the Light Gauge Slitting Line is widely used in the automotive industry for producing precise metal strips for car panels, engine parts, and chassis components. It also plays an essential role in the construction industry for manufacturing roofing sheets, wall cladding, and other architectural elements. Additionally, it is utilized in appliance manufacturing for producing parts for refrigerators, washing machines, and air conditioners.

With its high-speed performance, superior accuracy, and automated operation, the Light Gauge Slitting Line provides a cost-effective and reliable solution for modern metal coil processing requirements, ensuring consistent product quality and enhanced production efficiency.

Articoli recenti